Expertise

At Unlimited Packaging & Displays our services include a range of expertise to deliver the best packaging and displays solutions to our clients.

Printing

UV coatings are cured, or dried, by exposing the coating to ultraviolet radiation. These coatings offer excellent gloss, chemical, and rub resistance.

Aqueous coatings are approximately 60% water and 40% solids. During the drying process, the liquids evaporate or are absorbed by the substrate, leaving the solids to form a thin film. Aqueous coatings are clear and odourless when dry.

Flexographic is the most common process for printing in the production of cartons. The use of this process is on the rise because it is a relatively simple process, and it allows the use of water-based & vegetable-based inks. Other advantages of flexographic printing include lower costs, the speed of production and a reduced environmental impact.

Foil stamping

Foil stamping adds elegance and value to packaging, turning the ordinary into the extraordinary. Available in a variety of colours and finishes. Foils can also be overprinted or embossed for even greater impact.

Embossing and Debossing

Specialty finishing techniques such as embossing or debossing lend distinction and depth to a product that sets it apart from the competition.

Die Cutting

Die cutting enables the manufacture of an almost endless variety of shapes and styles. Utilizing die cuts, scores, punched holes, partials cuts, and perforations, we can create a variety of beautifully folding carton designs.

Windowing

Rigid and flexible (cellophane-type) windows add a whole new dimension to packaging, creating a visible link between the packaging and the product itself.

Gluing

Our capabilities range from gluing the most intricate folding carton designs in one pass to the application of peel n seal tapes.

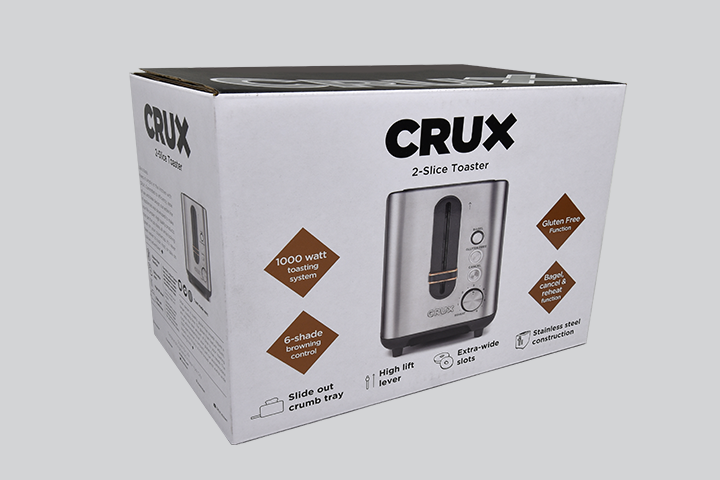

Litho Corrugated

This process creates the

highest quality lithographic print decoration on a corrugated carton. Typically used in the produce & beverage industry.

Prepack

To ensure the production and distribution of pre-packs run smoothly, we put them to the test through freight testing to make sure they’ll arrive in-store as good as new.

Prototyping

We create prototypes of all packaging and displays to help us refine and test the final design. To ensure structural integrity, we perform thorough weight testing before production.